Description

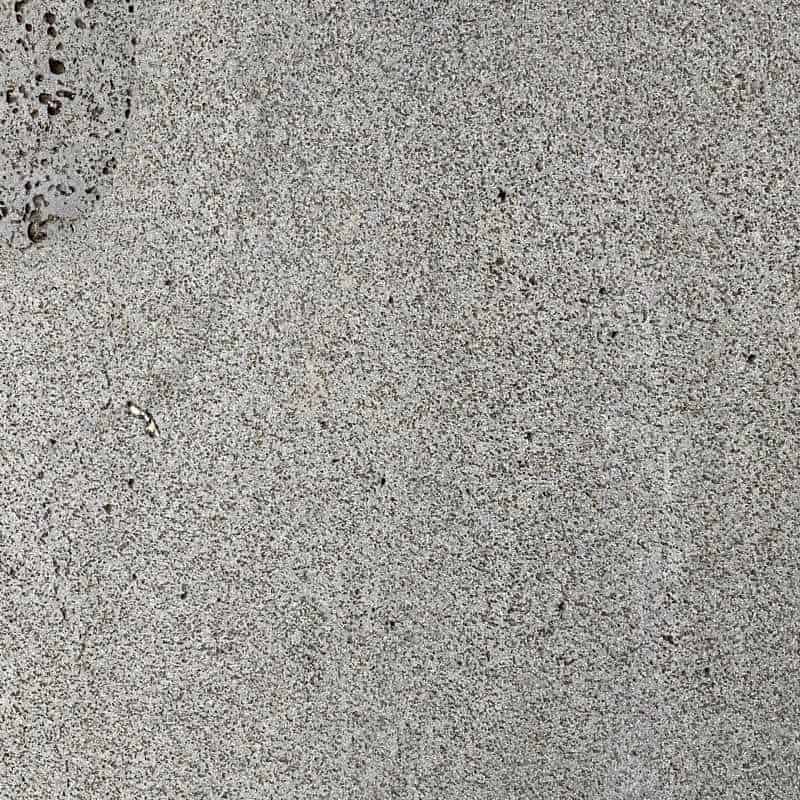

European Bluestone: Premium Grade (Diamond Sawn with a Lightly Honed Finish)

Elevate your project with the refined elegance and precision of our Premium Grade European Bluestone. Crafted for high-end residential, hospitality, and designer commercial spaces, our Premium Grade Bluestone offers a sophisticated alternative to standard finishes. Sourced for its quality and durability, this stone undergoes a meticulous light honing process using #200 grit diamond pads. The result is a stunningly uniform surface colour, free from saw marks, providing a clean, contemporary aesthetic that exudes luxury.

Why Choose Premium Grade Lightly Honed?

Superior Aesthetics: Experience a more refined look with significantly fewer “catspaw” (natural air holes). This leads to a cleaner, more uniform surface that requires minimal on-site filling, saving you time and labour during installation.

Precision Engineering: Benefit from tighter dimensional tolerances (±1.5 mm thickness). This exceptional accuracy allows for precise joints, tight alignment, and minimal grout lines, perfect for projects where architectural detail is paramount.

Safety & Durability: Maintain peace of mind with a P4 non-slip rating, making it ideal for both pedestrian traffic and wet areas. Its hard, dense composition ensures long-lasting performance in even the most demanding environments.

Timeless Colour Palette: Enjoy a beautiful shade similar to Australian Bluestone—slightly lighter than Chinese varieties—providing a classic yet modern feel to any design.

Heat Resistant: Naturally tolerant of typical outdoor heat exposure, ensuring your surfaces remain beautiful and functional throughout the seasons.

- Lighly Honed: We have lightly honed the diamond sawn finish to eliminate any saw marks on the tiles surface bringing it inline with its PREMIUM overall appearance and specs, whilst keeping its HIGH non slip rating of R11.

The Professional’s Choice

When your project demands the highest level of finish and predictability, specify our Premium Grade Lightly Honed European Bluestone. It’s the investment that pays off in a superior visual result and a more efficient installation process.

Ideal Applications:

High-end residential patios and walkways

Luxury pool surrounds and wet areas

Sophisticated hospitality interiors and exteriors

Designer commercial cladding and paving

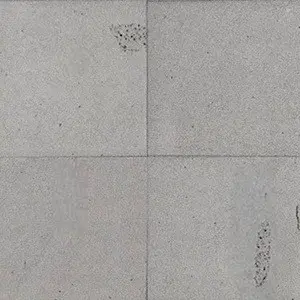

EUROPEAN STANDARD GRADE DIAMOND SAWN V's PREMIUM GRADE LIGHTLY HONED

European Bluestone — Standard Grade (Diamond Sawn Surface) vs Premium Grade (Lightly Honed Finish)

STONE & SLATE DISCOUNTS PL — ESTABLISHED in 1986.

Quality stone, trusted since 1986.

When selecting European Bluestone for a project, the finish and grade you choose affects the look, tolerances and how much finishing/filling will be required on site. Below is a simple, side-by-side explanation of what to expect from our Standard Grade Diamond Sawn Surface and our more refined Premium Grade Lightly Honed finish.

At a glance — similarities

Both grades share the same core performance characteristics that make European Bluestone such a popular paving and cladding material:

P5 non-slip rating — both achieve a P5 rating suitable for pedestrian traffic and wet areas.

Slight heat resistance — both grades tolerate typical outdoor heat exposure.

Hard & dense — both are durable and appropriate for residential and commercial applications.

Colour family — both are a similar shade to Australian Bluestone and are slightly lighter than typical Chinese Bluestone.

Major differences — what sets Premium apart

1. Fewer catspaw / air holes

Premium Grade: FAR fewer catspaw (small surface voids or air holes), which reduces the need for extensive filling, improves the finished appearance and gives a cleaner, more uniform surface.

Standard Grade: More natural catspaw is present — this is a normal characteristic of the stone but may require additional filling on exposed faces or in very fine finishes.

2. Cutting and dimensional accuracy

Premium Grade: Cut and finished to tighter tolerances — ±1.5 mm thickness and consistent dimensions. This makes Premium a better choice for projects where precise joints, tight alignment or minimal grout lines are required.

Standard Grade: More variation in thickness/dimensions is typical of a diamond-sawn product and can be acceptable for rustic or less precision-critical installations.

3. Surface appearance and finish

Premium Grade: Lightly honed using #200 grit diamond pads, producing a uniform surface colour with no visible saw marks. The result is a refined, contemporary aesthetic with a smooth, even face.

Standard Grade: Diamond-sawn surface retains the sawing texture/marks. This gives a more industrial or traditional saw-cut look which can be attractive where a slightly more textured appearance is desired.

Practical outcome for installers & specifiers

Appearance — Choose Premium if you want a consistent, clean finish with minimal visible defects or saw marks. Choose Standard if the saw-cut character is acceptable and you’re working to a tighter budget.

On-site work — Premium typically requires less remedial filling and face work, saving time in final finishing. Standard may need additional filling or attention to achieve a very smooth appearance.

Tolerance critical projects — When tight joint widths or thin grout lines are important, Premium’s ±1.5 mm tolerance makes installation easier and results more predictable.

Cost vs finish — Standard Grade (diamond sawn) is cost-effective and fit for many projects. Premium Grade costs more but returns savings in labour for finishing and delivers a superior visual result.

Quick comparison table

| Feature | Standard Grade — Diamond Sawn Surface | Premium Grade — Lightly Honed Finish |

|---|

| P5 non-slip rating | ✔︎ | ✔︎ |

| Heat resistance | Slight | Slight |

| Hardness / density | Hard & dense | Hard & dense |

| Shade (vs Aus/Chinese) | Similar to Australian Bluestone; slightly lighter than Chinese | Same |

| Catspaw / air holes | More common | FAR less |

| Dimensional tolerance | More variation | ±1.5 mm thickness & better dimensional control |

| Surface look | Saw marks visible | Uniform colour; no saw marks (lightly honed with #200 grit) |

| Typical use | Budget-conscious projects, rustic/industrial look | High-end finishes, tight tolerances, minimal on-site filling |

Recommendation

Specify Premium Grade Lightly Honed when appearance, tight jointing and minimal finishing are priorities — ideal for high-end residential, hospitality or designer commercial projects.

Specify Standard Grade Diamond Sawn when the saw-cut aesthetic is appropriate, or when budget and a more textured surface are the overriding considerations.

INSTALLATION

RECOMMENDED INSTALLATION TECHNIQUES FOR BLUESTONE

Please use one of the following adhesives IF installing in the adhesive is preferred…..

If you prefer to install your pavers in traditional sand and cement style follow these instructions to the letter:

ARDEX | CONSTRUCTION CHEMICALS | MAPEI

– Select one of the adhesives above (ALL are rapid setting adhesives) and simply mix as per manufactures specifications then 10mm notch the adhesive onto the back of EVERY tile (ensuring 100% coverage).

– Let the adhesive set( the ones above set rapidly), usually around 3-4 hrs and then install the tiles as per your usual technique into the wet sand and cement mix. IF you don’t use a rapid setting adhesive you must allow a minimum of 12 hrs before laying into the wet mix of sand and cement.

– This system minimises the risk of any of the tiles warping slightly due to being moisture sensitive or being excessively hot at time of installation.

– IF installing in sand and cement we recommend adding F-LOC to the mixture, this will reduce the chance of any efflorescence (calcium hydroxide) migrating

to the surface of the grout or tile. Tech Specs www.efflock.com.au.This can be purchased from Bunnings

– GROUTING should ONLY occur IF the tiles have been completely dry for at least 4 days in a row.

– IT IS NOT acceptable to blow the water out of the joints and then grout as you WILL have effluence issues, possibly warping issues, picture framing due to trapped excessive moisture.

– You must of course follow the Australian Tiling Standards in regard to incorporating expansion joints into your tiling. Failure to do so WILL lead to drummy and lifting tiles.

Sealing:

Highly recommended around BBQ areas or when the blue stone tiles are installed as internal floor tiles. Bluesetone pavers and tiles can be sealed with an invisible penetrating sealer to assist in the easy ongoing clean up of the stone pavers. We recommend sealing your Bluestone pavers with Tasman’s STONE SHIELD ( invisible no colour change penetrating seraler) This is also available at Stone & Slate Discounts. Cleaning prior to sealing we recommend a high pressure wash only, please ensure that you keep the jet nozzle around 250mm-300mm above the pavers at all times. DO NOT use a colour enhancing sealer on your bluestone as they tend to highlite any saw marks not visible to the naked eye and are generally harder to use and can be problematic.

Cleaning:

Do not use Hydrochloric acid for clean up as this can cause minerals present in the stone to react adversely.Bluestone responds well to high pressure cleaning with a domestic machine, please keep the nozzle about 300mm minimum away from face of the bluestone pavers and tiles. Please ensure you use a blade not pin type head on the pressure cleaner, and ensure you pressure wash the ENTIRE paver.

Maintenance:

Just sweep when needed. Bluestone responds well to high pressure cleaning with a domestic machine, please keep the nozzle about 300mm minimum away from face of the bluestone pavers and tiles. Please ensure you use a blade not pin type head on the pressure cleaner, and ensure you pressure wash the ENTIRE paver. A solution of mild detergent and water can be applied prior to pressure cleaning.

#200 Grit Honed Finish Explained

Specifier’s Note: #200 Grit Sawn and Lightly Honed Bluestone

Project Application: Premium Pool Coping, Luxury Alfresco, and High-Traffic Transitions.

1. The Aesthetic Advantage

Unlike standard “Honed” bluestone (which is often polished to #400 grit or higher, resulting in a lighter, slippery surface), the #200 Grit process is a deliberate “light-honing.”

Depth of Color: It saturates the stone’s natural basaltic minerals, achieving a rich Charcoal/Midnight hue that beautifully contrasts with turquoise pool water.

Surface Refinement: It removes the visible circular saw marks found on “Sawn” stone, providing a sleek, minimalist finish that suits contemporary Melbourne architecture.

2. Safety & Compliance (P4 / R11)

The #200 grit level is specifically engineered to meet the Australian Standard AS 4586:2013 for outdoor wet areas.

Mechanical Grip: The coarser grit leaves microscopic “peaks” on the stone surface. This ensures a P4 slip rating, providing secure traction for bare feet even when the surface is saturated with chlorinated or salt water.

The “Sweet Spot”: It is the highest level of honing achievable while still maintaining a legal safety profile for outdoor pool surrounds.

3. Performance & Maintenance

Salt Resistance: Being a high-density volcanic basalt, this stone is naturally resistant to salt-water environments, preventing the “pitting” seen in softer stones like sandstone.

Thermal Comfort: The honed surface is smoother than sandblasted alternatives, making it more comfortable for bare skin (sitting on pool edges) while still dissipating heat effectively in the Victorian climate.

Reduced Algae Trapping: Because the surface is flatter than “Natural Split” or “Sawn” finishes, there are fewer deep crevices for dirt and organic matter to settle in, significantly reducing the frequency of deep cleaning.

Architectural Specification Clause

“External stone paving to be #200 Grit Lightly Honed Natural Bluestone (Basalt). Stone must achieve a minimum P4 slip resistance rating in accordance with AS 4586:2013. Finish to be uniform with all diamond saw marks removed. Stone is to be sealed with a premium breathable penetrating sealer (e.g., Aqua Mix Sealer’s Choice Gold or similar) to protect against organic staining without altering the slip rating.”