Feel free to read the blog or download our installation guide here

Guide to Installing Natural Travertine Tiles and Pavers

Installing natural stone pavers requires precision and the right tools to ensure a successful installation. Here is a step-by-step guide along with a list of tools you will need:

Tools Required:

- Measuring tape

- Chalk or marking tool

- Rubber mallet or wooden block

- Level

- 12mm notch trowel

- Grout float

- Soft brush or sponge

- Bucket

- Damp cloth or sponge for cleaning

- Safety glasses and gloves (recommended for handling materials and using adhesives)

- Dust mask when mixing sand and cement or adhesive and grout.

- Wet saw (can be rented from Kennards Hire) for cutting stone pavers

- Cement mixer or wheelbarrow for mixing sand and cement (for larger jobs)

- Adhesive, grout, and sealer products as per manufacturer’s directions

Installation Steps:

- Preparation:

- Assess the area where you plan to install the natural travertine tiles and pavers and ensure it is suitable for the intended purpose.

- If there is an existing concrete slab in good condition, proceed with laying the tiles or pavers in adhesive or sand and cement.

- If no concrete slab exists, remove existing materials and debris to a depth of approximately 150mm. Level off the area with a compacted 100mm road base. Proceed to lay the travertine pavers in a slurry of sand and cement.

- For 12mm thick stone tiles: Apply adhesive using a 12mm notch trowel onto an existing concrete slab. Remember to butter the back of EVERY tile during the laying process.

- For 30mm thick travertine stone pavers: Choose one of the following methods:

- Adhesive method: Apply adhesive using a 12mm notch trowel onto an existing concrete slab.

- Slurry or wet mix method: Create a slurry or wet mix of 4 parts sand and 1 part cement with 1 litre of bonding agent. Spread the mixture onto a prepared crushed rock base (100mm). We strongly recommend buttering the back of every tile or paver with adhesive prior to laying into the wet mix of sand and cement.

- Laying the Pavers:

- Carefully place the natural stone pavers onto the adhesive or slurry, ensuring proper alignment and spacing.

- Use a rubber mallet or wooden block to gently tap the pavers into place, ensuring they are level and secure.

- If laying into adhesive, use a 12mm notch trowel and use plastic spacers of 5mm for grout joint spacing. Simply push and twist the tile into the adhesive bed. DO NOT use a rubber mallet.

- Grouting:

- For all thicknesses: Fill the gaps between the pavers with a manufactured premix sanded grout or a 5:1 mix of sand and cement with an EFFLOC additive.

- Apply the grout using a grout float, making sure to fill all the joints completely.

- Remove any excess grout from the surface using a damp sponge or cloth, being careful not to disturb the newly installed pavers.

- Curing and Cleaning:

- Allow approximately 5 days for pavers laid in adhesive or 2 weeks for pavers laid in sand and cement to cure before proceeding with cleaning and sealing.

- Clean the travertine tiles using a mild detergent and water, scrubbing gently with a soft brush or sponge to remove any remaining grout residue or stains. In case of stubborn grout marks, use a domestic gernie to clean the stone.

- Rinse thoroughly with clean water to ensure all cleaning agents are removed.

- Sealing (if required):

- Depending on the type of natural stone and desired level of protection, consider applying a suitable sealer to enhance the appearance and provide additional durability.

- Follow the manufacturer’s instructions for the specific sealer, applying it evenly and allowing it to dry completely before use.

Remember to always refer to the manufacturer’s guidelines for the specific natural travertine stone pavers you are installing, as recommendations may vary. Following these steps and adhering to the directions on adhesive, grout, and sealer products will help ensure a successful and professional-looking installation of your natural travertine paving.

-

Sale!

Ivory Travertine Tiles “A” Grade

Rated 5.00 out of 5$53.90 – $133.00 Select options This product has multiple variants. The options may be chosen on the product page -

Sale!

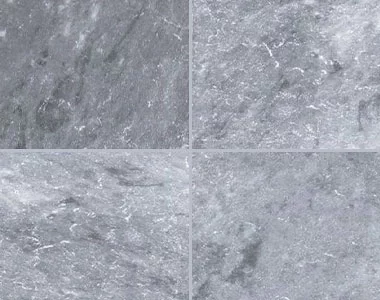

Silver Travertine Tiles

$66.00 – $120.00 Select options This product has multiple variants. The options may be chosen on the product page -

Sale!

Shell White Limestone

$99.00 – $140.00 Select options This product has multiple variants. The options may be chosen on the product page -

Sale!

Ivory Travertine Tiles – Premium Grade

$61.60 – $63.80 Select options This product has multiple variants. The options may be chosen on the product page -

Sale!

Classic Mix Travertine Tiles

$69.00Original price was: $69.00.$49.50Current price is: $49.50. Select options This product has multiple variants. The options may be chosen on the product page -

White Limestone- Capri

Rated 5.00 out of 5$99.00 – $160.00 Select options This product has multiple variants. The options may be chosen on the product page -

Sale!

Ivory Travertine French Pattern “A” Grade

Rated 5.00 out of 5$53.90 – $89.00 Select options This product has multiple variants. The options may be chosen on the product page -

Pearl Grey Limestone Tiles

$83.00 – $140.00 Select options This product has multiple variants. The options may be chosen on the product page -

Sale!

Cheap Travertine Tiles- Rustica

$49.00Original price was: $49.00.$29.00Current price is: $29.00. Select options This product has multiple variants. The options may be chosen on the product page -

Sale!

Shell White French Pattern Tiles

$114.00Original price was: $114.00.$99.00Current price is: $99.00. Select options This product has multiple variants. The options may be chosen on the product page -

Sale!

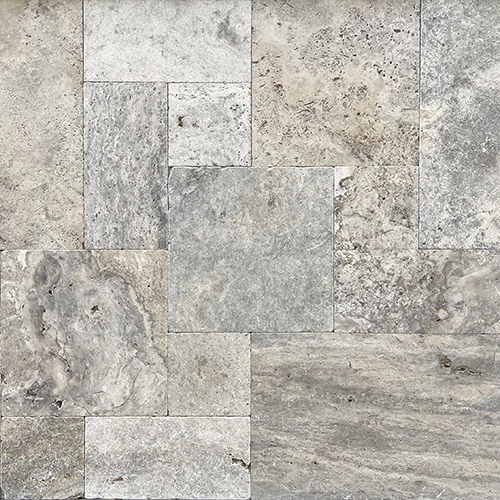

Silver Travertine French Pattern

$66.00 – $120.00 Select options This product has multiple variants. The options may be chosen on the product page -

Antique Travertine Tiles

$56.00 – $108.90 Select options This product has multiple variants. The options may be chosen on the product page -

Noce Travertine Tiles

$59.00 – $120.00 Select options This product has multiple variants. The options may be chosen on the product page -

Antique Travertine French Pattern

$56.00 Select options This product has multiple variants. The options may be chosen on the product page -

Ivory Travertine (Filled & Honed)

$79.00 – $99.00 Select options This product has multiple variants. The options may be chosen on the product page -

Travertine Loose Cladding

$119.90 – $139.70 Select options This product has multiple variants. The options may be chosen on the product page

-

Sale!

Travertine Crazy Paving- Ivory

Rated 5.00 out of 5$59.40 – $79.00 Select options This product has multiple variants. The options may be chosen on the product page -

Sale!

Silver Travertine Crazy Paving

$129.00Original price was: $129.00.$79.00Current price is: $79.00. Select options This product has multiple variants. The options may be chosen on the product page

-

Sale!

Ivory Travertine Drop Edge Pool Coping- No Joins- 1 Solid piece of Stone

$59.40 – $89.00 Select options This product has multiple variants. The options may be chosen on the product page -

Sale!

Silver Travertine Drop Down Pool Coping- No Joins- 1 Solid piece of Stone

$66.00 – $99.00 Select options This product has multiple variants. The options may be chosen on the product page -

Noce Travertine Drop Edge Pool Coping- No Joins- 1 Solid piece of Stone

$66.00 – $99.00 Select options This product has multiple variants. The options may be chosen on the product page -

Antique Travertine Drop Edge Pool Coping- No Joins- 1 Solid piece of Stone

$66.00 – $99.00 Select options This product has multiple variants. The options may be chosen on the product page -

Sale!

Ivory Travertine Tumbled Pool Coping

$34.00Original price was: $34.00.$29.70Current price is: $29.70. Select options This product has multiple variants. The options may be chosen on the product page -

Sale!

Noce Travertine Bullnose Pool Coping

$42.00Original price was: $42.00.$36.00Current price is: $36.00. Select options This product has multiple variants. The options may be chosen on the product page -

Sale!

Ivory Travertine Bullnose Pool Coping

$37.00Original price was: $37.00.$33.00Current price is: $33.00. Select options This product has multiple variants. The options may be chosen on the product page -

Sale!

Silver Travertine Bullnose Pool Coping

$43.00Original price was: $43.00.$37.00Current price is: $37.00. Select options This product has multiple variants. The options may be chosen on the product page

Learn More About Travertine Tiles & Pavers

How To Install Travertine Tiles?

How To Clean Travertine Tiles?

Travertine Tiles Prices in Australia

Different Types of Grout for Travertine Tiles & Pavers

Simple Tricks To Keep Your Travertine Clean

Understand Types of Travertine Floor Tiles

Travertine V/S Porcelain Tiles

Need A Hand With Your Travertine?

Call : 03 9706 9767

Our friendly Natural Stone Paver Experts are here to help you get the best paving solution for your project!

We’re available: Mon – Fri 7.30am – 5pm & Sat 9am – 4pm.

After hours please contact us here.